MTP is a comprehensive first-class manufacturing company supplying precision machined components up to fully finished status.

We serve most of worldwide known original equipment manufacturers in commercial aviation market from transport to large civil, regional and business jets.

We supply precision engine components from intake to exhaust for every major program world-wide.

MTP continues to combine investment in highly skilled people with the latest techniques and equipment to provide our customers with innovative advanced technology solutions. In an industry that is safety- critical, we comply with the most stringent quality standards.

With our commitment to lean initiatives we aim to deliver quality products, on time, every time and at a competitive price.

MTP has long-term supply agreements with all leading engine companies and we equip gas turbine engines from intake to exhaust drawing on key technologies and capabilities.

Excellence in machined components

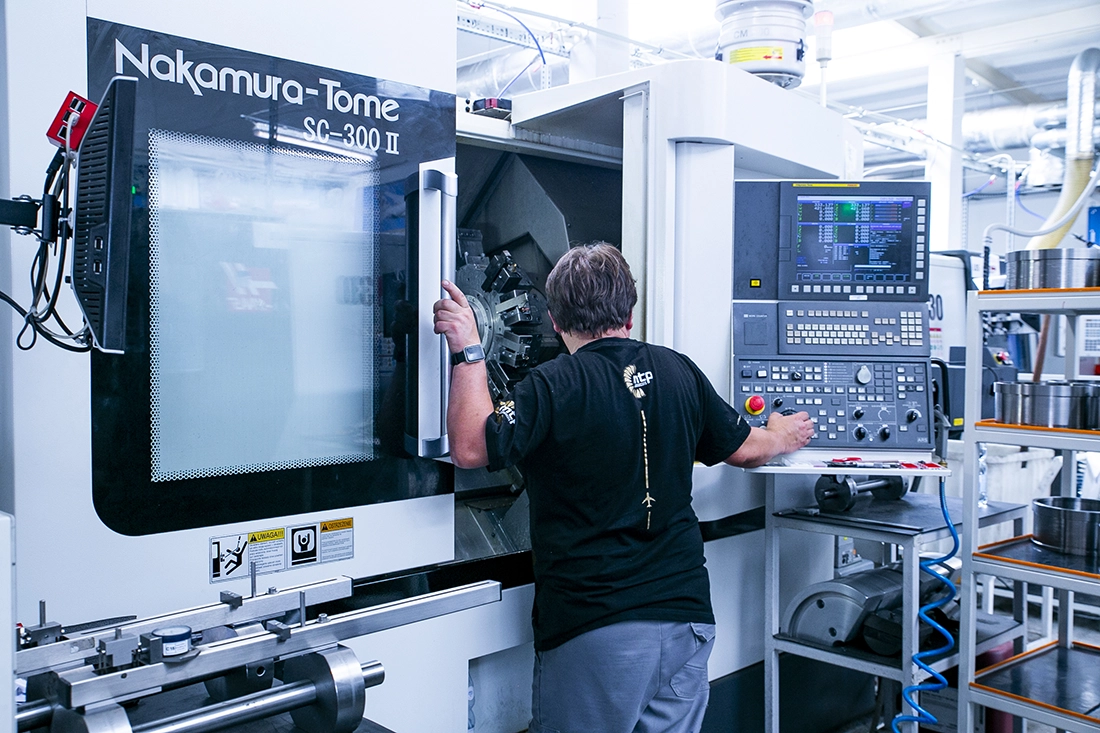

We are a comprehensive, first-class manufacturing facility maintaining high levels of investment in state-of-the-art machine tools, including full 5 axis CNC capability.

Components are supplied up to fully finished status ready for direct OEM or sub-tier program supply on a global basis.

A wide range of precision machined airframe and engine components are produced at our modem, fully equipped facility in a varied range of „difficult-to-work” aerospace materiaIs.

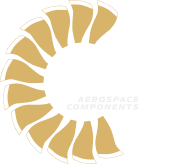

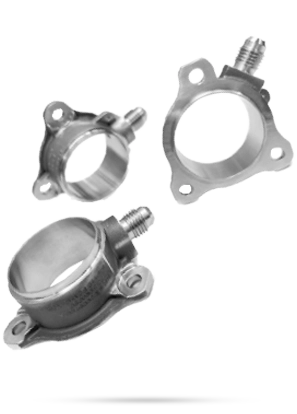

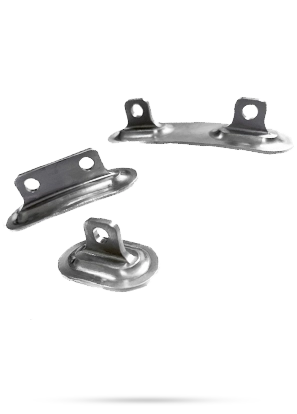

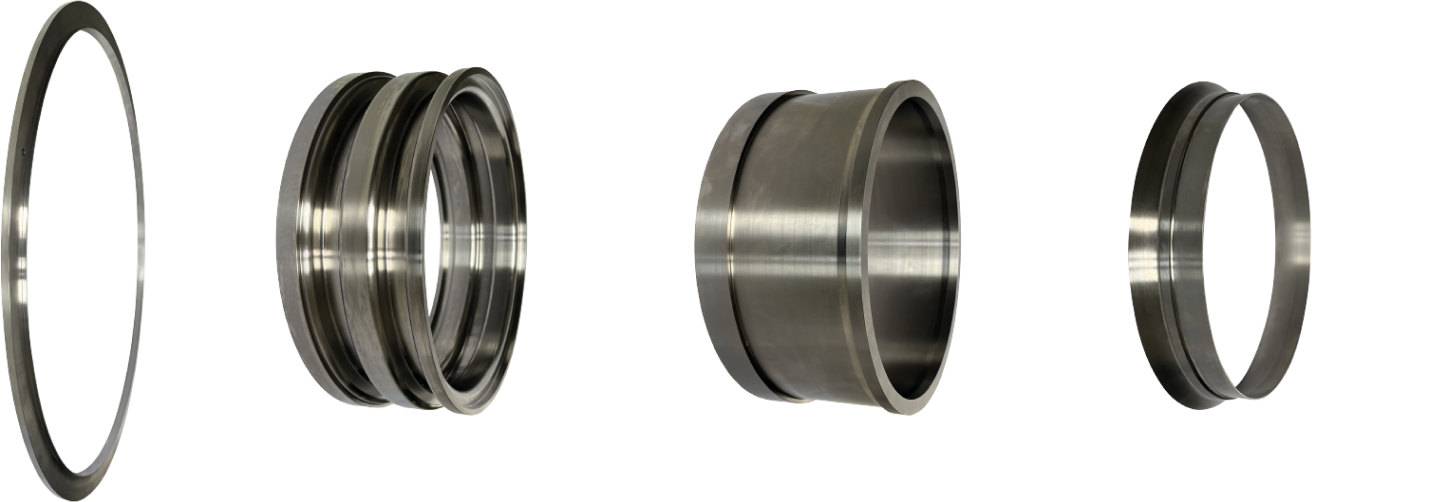

Products include engine and landing gear components, typically:

• Prismatics

• Rings (static and rotating)

• Fuel injection components

• Flanges

• Housings

• Bosses

• Pins and retainers Engine externals

• Landing gear components: torsion links, sleeves and bushes

OUR WORKS

In an even more competitive market we offer tailored to your needs, geared to drive out cost and improve quality and performance.

Facilities and capabilities.

High levels of recent investment in the latest CNC machine tools and systems ensures components are manufactured to consistently high standards whilst maximising throughput and minimising through-costs.

CNC capabilities include:

• Turning (VTL&Horizontal)-2 & 4 axis (size range up to 850mm)

• Milling -3,4 & 5 axis (size range up to 600mm in full 5D machining)

Additionally a range of conventional equipment is available for complimentary machining operations

In-house support facilities include:

• Detail finishing operations (deburr and polish)

• Part marking

• In-house tooling manufacture

External special aerospace -approved process resources are locally available.

The Iatest techniques are employed to achieve and maintain long-term customer relationships.

Fully integrated services are tailored to individual need and are geared to drive out cost and improve performance throughout all operations.

These techniques include:

• Cellular manufacture

• Fast response cells

• Continuous improvement programs

• Concurrent engineering

• Fuli commitment to lean initiatives

• Just-in-time principles

• Total quality management

• Systems integration and monitoring

Production control and engineering

MTP operates fully integrated computerized MRP systems driving purchasing, logistics, planning, manufacturing, process control, costing and finance.

Full traceability of components from raw material through to finished product is achieved.

Customer service

The understanding of every aspect of our individual customer’s commercial needs and service requirements is crucial to our business performance. As an integral part of our Continuous improvement program customer service is paramount, and as a result customers benefit from improved, tailored services throughout all aspects of our business.

Supply chain management

Our logistics team handles the complete supply chain from material purchase through long and short term capacity planning, sub -contract supply management to the despatch of the right components on-time.

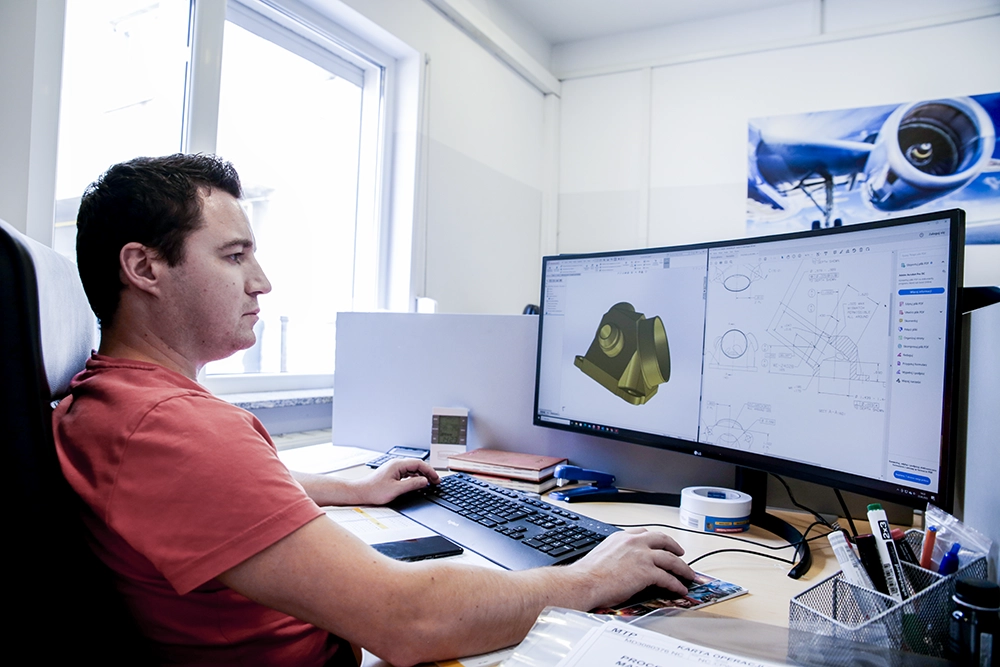

Machine programming is carried out using advanced CNC systems with in-built geometry creation.

We utilize the latest versions of EdgeCam, CAD/CAM, Designer and Solid Works.

We have the expertise to effectively manage and execute sub-contract support operations using local quality and process accredited sub-contract supply sources to provide comprehensive solutions to a wide variety of finishing operations.

OUR CURRENT CERTIFICATES

MTP is accredited to and holds AS9100 Aerospace Standard approval.

Customer focussed, cost-effective

manufacturing solutions…

Working with our customers on a „make-to-print” basis, we employ the latest technologies to provide the most cost effective

manufacturing solution.

Components, kits, assemblies, kanbans and packages are managed through our manufacturing processes to provide a comprehensive value – added solution to customer needs at lowest cost.

Manufacture of a wide rangę of complex components is carried out utilizing a comprehensive range of CNC machining centres.

Dimensional CNC milling capabilities of 1500 x 660 x 650mm and CNC turning centres capable of machining products up to 650mm are maintained.

Materials expertise

We have extensive experience in the machining of exotic high temperature alloys including cobalt nickel, titanium, aluminium and stainless steels typically:

• Alloy 718

• Alloy 625

• Cres Steels

• Cobalt Alloys

• Bronze Alloys

• Titaniums

• Aluminiums

• Stainless Steels

OUR WORKS

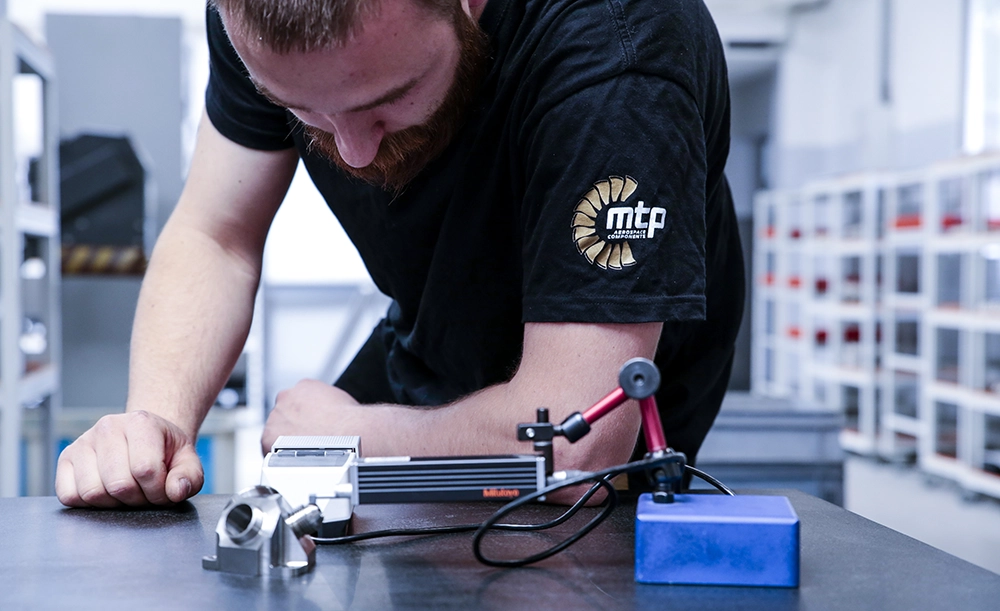

Ouality is assured

Ouality control is supported by a range of inspection and measurement equipment to qualify production output.

Equipment includes:

• CNC Mitutoyo co-ordinate measurement machines

• Optical microscopy

• Shadowgraph

• Hardness testing

We recognise that quality is measured by the ability to meet customer requirements in every aspect from the outset. Operators are trained to inspect their own and each others work, employing SPC technigues to batch production.

MTP is accredited to and holds AS9100 Aerospace Standard approval.

DQR program is implemented and maintained for main customers.

The company also holds many individual customer quality supply approvals including:

• Pratt&Whitney

• GE Aviation

The company works according to ISO 14001 environmental standard.